Infrastructure

LNM AUTO INDUSTRIES, based in Faridabad, Haryana, is a premier manufacturer of precision engineering products for industries like automotive, mining, and construction. With advanced facilities for forging, die casting, machining, and heat treatment, we deliver high-quality components tailored to customer needs.

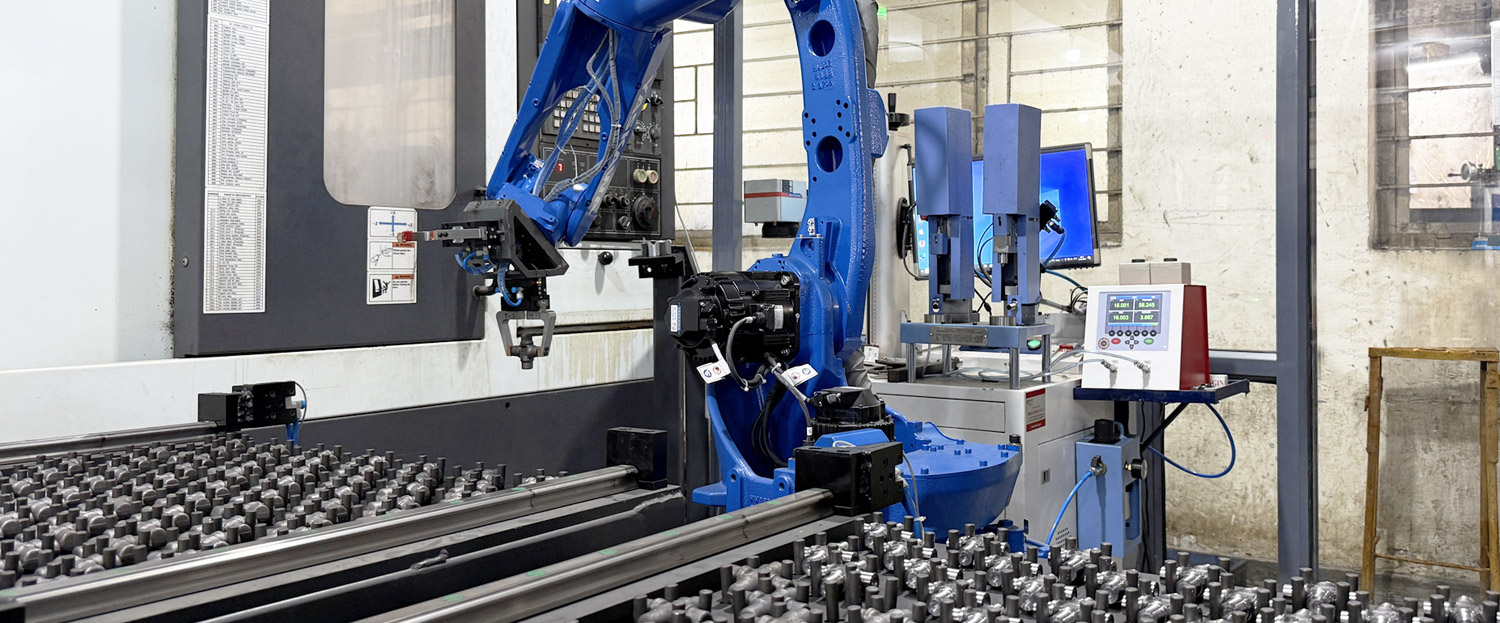

In-House Automation

At LNM Auto Industries, we continuously invest in smart manufacturing solutions to enhance productivity, precision, and operator safety. One of our key innovations is the in-house designed and installed Pick & Place Gantry System and Robotic Integration for CNC machines. Our Capabilities Include: Custom-Designed Automation SystemsEngineered and developed in-house by our skilled team to suit… <a class="more-link" href="https://lnmauto.com/infrastructure/in-house-automation/">Continue reading <span class="screen-reader-text">In-House Automation</span></a>

View

Part Process Design

At LNM Auto Industries, Part Process Design is a critical foundation of our manufacturing excellence. We follow a structured, engineering-driven approach to design robust, cost-effective, and high-yield processes for every component we manufacture. Our Capabilities Include:

View

Warehousing

At LNM Auto, we understand that timely delivery is just as critical as product quality. That’s why we offer strategic warehousing solutions designed to support Just-in-Time (JIT) deliveries, optimize inventory flow, and reduce lead times for our global customers. As a trusted precision components manufacturer and exporter, our warehousing infrastructure is built to ensure supply chain reliability, especially for customers… <a class="more-link" href="https://lnmauto.com/infrastructure/warehousing/">Continue reading <span class="screen-reader-text">Warehousing</span></a>

View

Surface Treatment

To guarantee long-term performance in harsh environments, LNM Auto offers a full suite of surface-treatment services seamlessly integrated into our forging and precision-machining lines. Each process is executed in ISO-certified facilities and backed by in-house testing for thickness, adhesion, and salt-spray life.

View

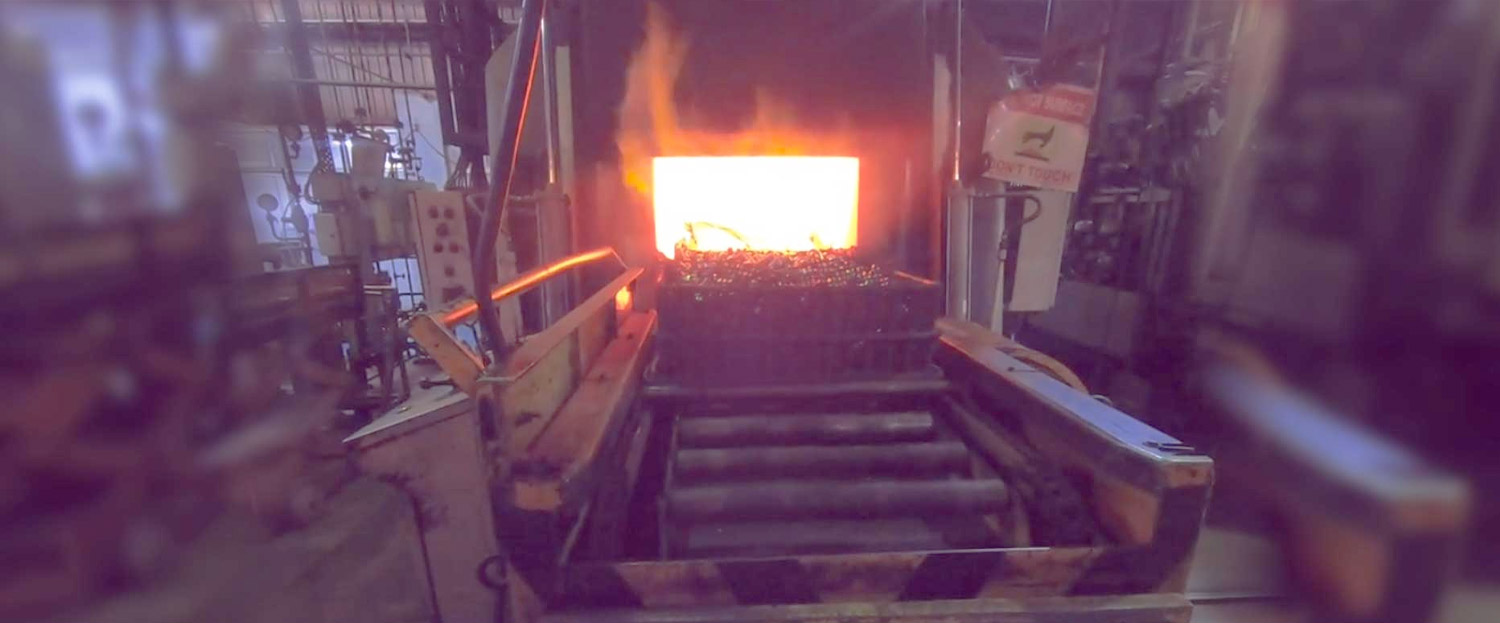

Heat Treatment

LNM Auto offers advanced heat treatment solutions as part of our integrated manufacturing process, ensuring that every component we produce meets the highest standards of strength, hardness, and wear resistance. Our in-house heat treatment capabilities allow us to precisely control metallurgical properties, improving both performance and reliability under extreme operating conditions. As a trusted heat treatment services provider… <a class="more-link" href="https://lnmauto.com/infrastructure/heat-treatment/">Continue reading <span class="screen-reader-text">Heat Treatment</span></a>

View

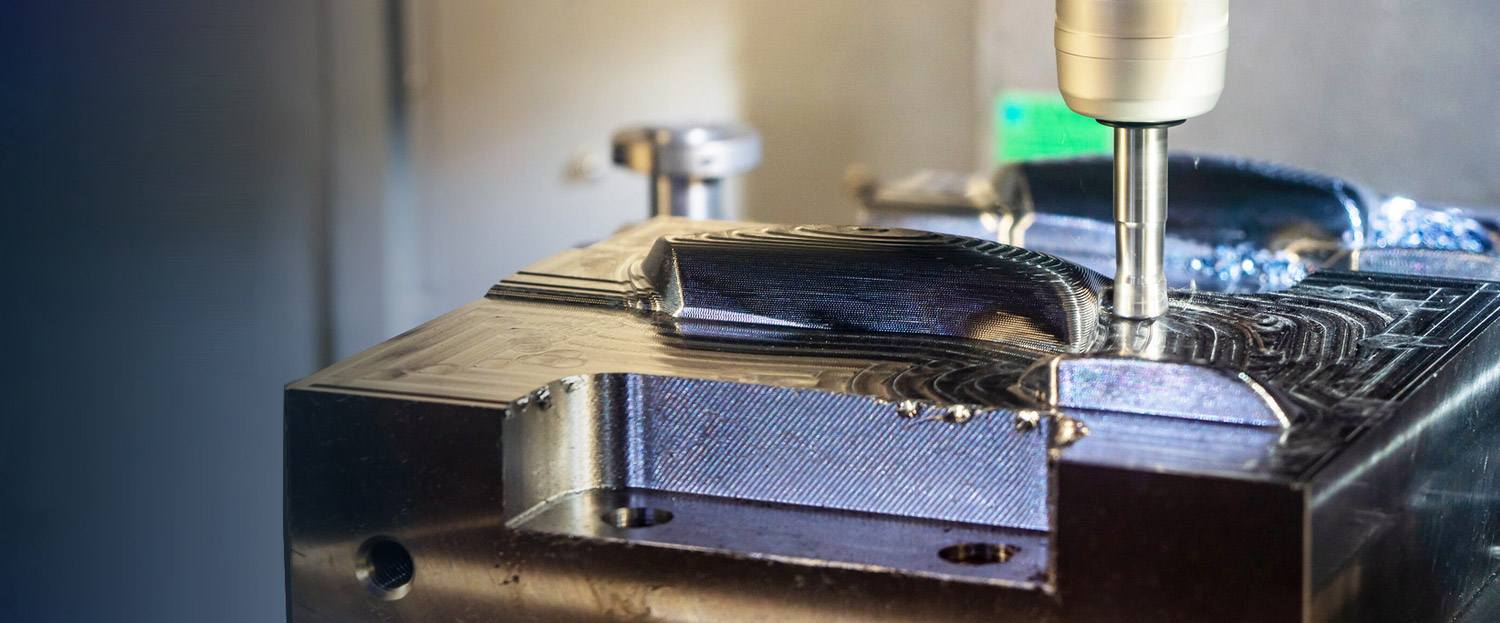

Precision Machining

At LNM Auto, we specialize in delivering high-precision machining services for industrial, automotive, agricultural, and off-highway components. With a vertically integrated setup and a strong quality focus, we manage the entire value chain — from raw material processing to final dispatch — under one roof. As a trusted precision machining manufacturer in India, we combine state-of-the-art CNC technologies… <a class="more-link" href="https://lnmauto.com/infrastructure/precision-machining/">Continue reading <span class="screen-reader-text">Precision Machining</span></a>

View

Precision Forging

Equipped with cutting-edge machinery for both Open Forging and Closed Die Forging, our advanced forging facilities ensure production of highly durable and accurate components for the agriculture, mining, automobile and heavy machinery industries. We understand the need of exceptional precision and deliver forgings that withstand the most demanding applications. Closed Die Forging (up to 30… <a class="more-link" href="https://lnmauto.com/infrastructure/precision-forging/">Continue reading <span class="screen-reader-text">Precision Forging</span></a>

View